Categroy List

Pre-filled Syringe Rubber Stoppers RNS/NS

- 产品描述

-

Short Description

A pre-filled syringe is a disposable syringe that is already filled with the single dose of medication the patient needs to inject. By avoiding filling the syringe from a vial, the process is faster, easier and more accurate. It is commonly used for dental local anesthesia, vaccines, diabetes, autoimmune diseases and cancer.

Medicinal rubber plungers are widely used as primary packaging for various types of medicines. However, some relatively high-end packaging products such as prefilled syringes require rubber plunger have higher requirements for compatibility. First Rubber Company supplied products will make sure that our rubber components for prefilled syringes will meet all necessary functions.

We offer our customers integrity sealing solutions with the highest quality for their syringe systems. We are specialized to supply rubber plunger stoppers, rubber-lined aluminum seals, and needle shield for prefilled syringe.

The stopper (plunger or bung) is made of rubber that can be of different qualities and types. Today two classes of rubber are mainly used for prefilled syringes: one is chlorobutyl rubber, the other made of bromobutyl rubber.

The cap is located at the opposite end of the cartridge from the rubber plunger, and it is contained into an aluminum metal ring. The lined rubber is typically made of the same kind as the plunger rubber (usually bromobutyl rubber)

Protecting the needle from external forces is another important aspect when it comes to injectables. Both our soft and rigid needle shield that ensure the needle will not damaged during production, filling, and distribution.

Specifications

Item

Drawing No.

Feature

Diameter

Spiral Diameter

Spiral Height

Total Height

Rubber Plungers for Prefilled Syringe Use

Φ6.9 YGF

Pointed & 3 Lines

6.90±0.1

4

4.5

7.65±0.2

Φ9.15 YGF

Pointed & 4 Lines

9.15±0.15

——

——

7.7±0.4

10ML

Three Edges &

4 Lines10.00±0.10

——

——

9.50±0.2

15ML

Pointed & 3 Lines

12.62±0.1

7.4

7

16.06±0.2

20ML

Pointed & 3 Lines

19.41±0.1

10.9

7

14.97±0.2

50ML

Pointed & 3 Lines

29.59±0.1

17.5

7.85

16.56±0.2

Item

Specifications

Feature

Outer Diameter

Inner Diameter

Total Height

Needle Sheath for Prefilled Syringe Use

Softness

Rubber

7

4.7

23

Hard

Inner with rubber and outer with plastic

8.15±0.10

4.7

25

Advantage

1.High cleanliness standard. Production under 100,000 class cleaning area,

2.Superior service system, with professional technical personnel, to provide customers with supporting and personalized services at any time;

3.Supply well-known pharmaceutical manufacturers home and abroad.

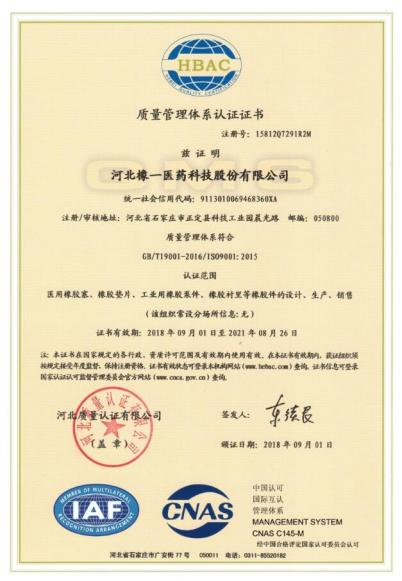

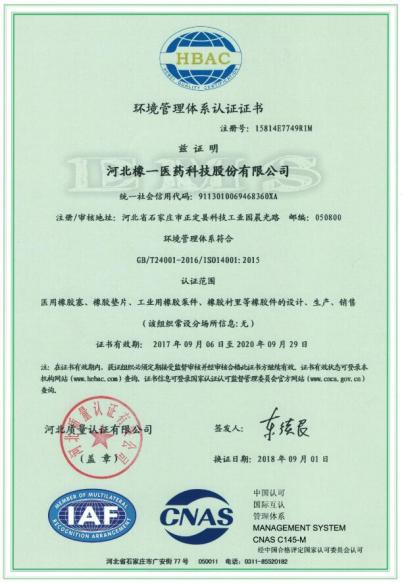

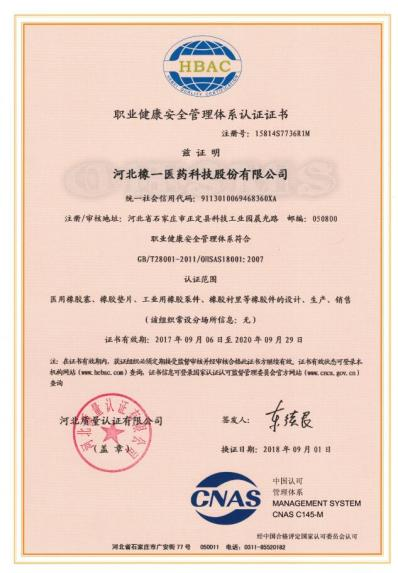

Certificates

ISO 15378 Certification

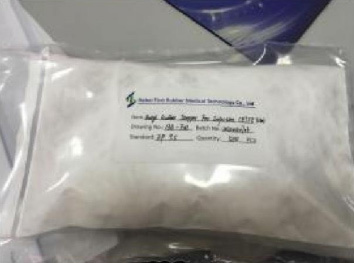

Packing Details

Inner packing is PE bag; Outer packing is carton.

Rubber plungers for prefilled syringes are essential components designed to ensure consistent drug delivery performance, airtight sealing, and reliable compatibility with sensitive pharmaceutical formulations. Manufactured using high-purity bromobutyl or chlorobutyl rubber, these plungers provide exceptional chemical stability, low extractables, and excellent resistance to moisture and gas transmission, making them ideal for modern injectable drug systems. Their precise dimensional accuracy and optimized surface finish help minimize friction within the syringe barrel, enabling smooth, controlled plunger movement during injection and ensuring consistent dosing accuracy for both low-viscosity and high-viscosity drugs.

To meet the stringent requirements of injectable formulations, rubber plungers are produced through advanced molding and curing processes that enhance mechanical strength, elasticity, and long-term sealing performance. They are often coated with medical-grade lubricants, such as silicone oil or fluoropolymer coatings, to reduce sliding resistance, prevent sticking, and improve overall injection comfort. For formulations sensitive to silicone oil, specially designed low-silicone or silicone-free plungers are available, offering stable performance without compromising the purity of biologics, vaccines, or protein-based drugs.

The materials used in rubber plungers undergo rigorous extraction, leaching, and compatibility testing to ensure they do not interact with medications or leach harmful substances during long-term storage. Pharmaceutical manufacturers often choose plungers that comply with international standards such as USP, EP, ISO 11040, and FDA regulations. These standards specify criteria related to sterility, biocompatibility, endotoxin levels, particulate matter, and mechanical properties, ensuring the plungers can be safely used in a wide range of therapeutic applications, including biologics, insulin, anticoagulants, vaccines, ophthalmic drugs, and emergency-use injectables.

In addition to sealing and movement functions, rubber plungers play a key role in maintaining container closure integrity (CCI) during transportation, storage, and temperature fluctuations. Their elasticity ensures consistent contact with the syringe barrel, preventing air ingress, leakage, or microbial contamination. This reliable barrier function is crucial for maintaining sterility and drug potency over extended shelf life. Some plungers incorporate special barrier films or multilayer structures to further reduce gas permeability and enhance compatibility with sensitive formulations.

Rubber plungers are available in a variety of sizes and configurations to suit glass and plastic prefilled syringes, including 1 mL long, 1 mL short, 3 mL, 5 mL, and larger capacities. Customized designs, such as double-radiused tips, vented structures, and reinforced cores, are also offered to meet specific drug delivery requirements. Manufacturers may also supply pre-sterilized plungers processed through validated steam, gamma, or EtO sterilization methods to support streamlined filling operations and reduce contamination risks in pharmaceutical production environments.

As prefilled syringes continue to gain global adoption for clinical, hospital, and home-use drug administration, the performance and reliability of rubber plungers become increasingly important. Their role extends beyond simple mechanical movement—they contribute directly to drug safety, dosing accuracy, patient comfort, and overall product quality. High-quality rubber plungers help ensure that injectable medications remain stable, sterile, and ready for immediate use, supporting safer and more efficient healthcare delivery worldwide.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.

Releate Products

undefined